To understand the difference between dense phase conveying and dilute phase conveying, especially in terms of fluid mechanics, and be able to accurately design and calibrate pneumatic conveying systems. Calibration speed and air pressure are very important in a pneumatic conveying system. The accuracy of the calibration largely depends on the type of material being conveyed.

What does dense phase conveyance mean?

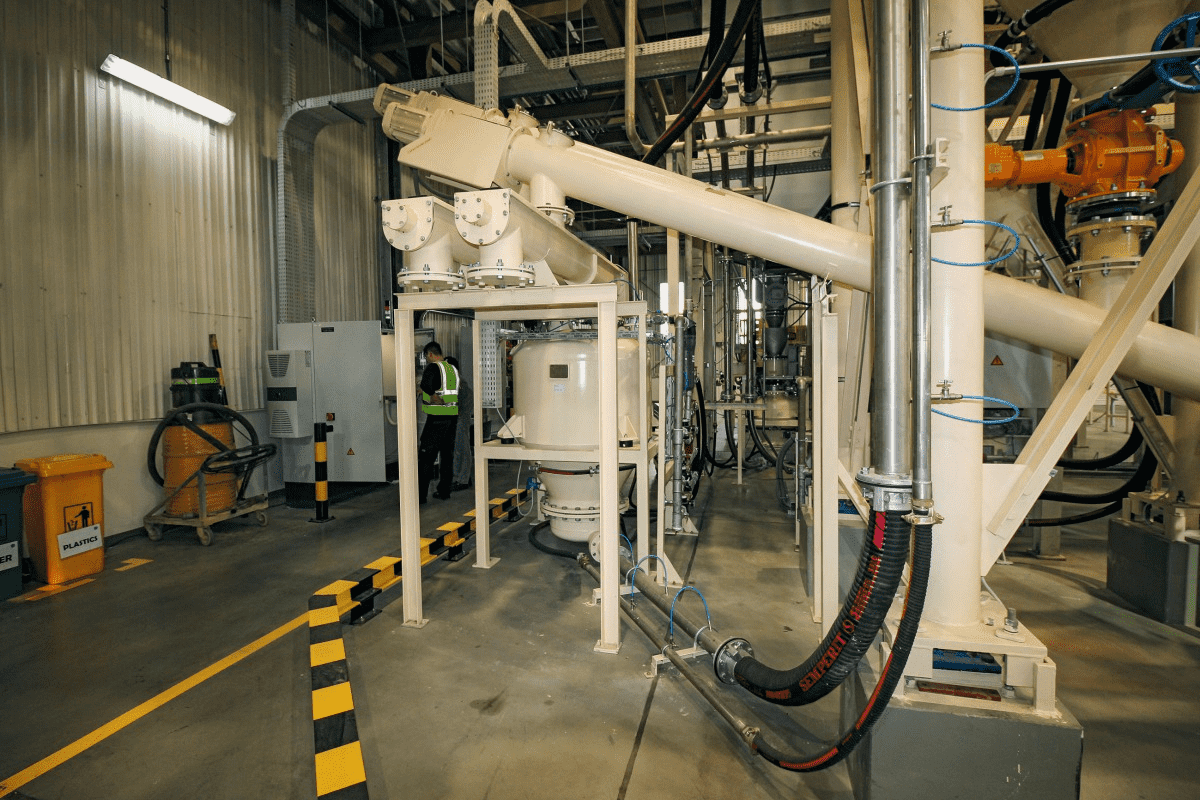

Dense phase conveying is a relatively new concept in the industry. Dense phase conveying, as the name implies, refers to a way of densely conveying bulk materials in a pipeline. In dense phase conveying, the product will not be suspended in the air, because the conveyed material is either too heavy or very abrasive, and a high air velocity must be maintained. This means that the products will be transported in the form of “waves”, “plugs” or “strands”, so that less wear is produced, so dense phase transportation is more suitable for fragile products.

What does dilute phase conveyance mean?

Dilute phase conveying involves conveying a large amount of dispersed materials, these particles are lighter and more abrasive. This means that compared with dense phase conveying, materials can be conveyed at a faster speed and higher pressure. For example, talc is lighter and less abrasive than plastic particles, so it can be transported at higher speeds and air pressures. In dilute phase conveying, a blower is used to convey the product into the system through airflow. The airflow just keeps the material flowing and prevents the material from depositing at the bottom of the pipe.

The difference between dense phase conveying and dilute phase conveying in pneumatic conveying

Some differences between dense phase conveying and dilute phase conveying are inevitable because they are inherent characteristics of the bulk material itself-for example, dilute phase conveying often handles lighter particles. The following are some of the main differences between dense phase conveying and dilute phase conveying:

1. Speed: The speed of dilute phase pneumatic conveying is usually faster than that of dense phase. Considering the abrasiveness of the particles carried, the conveying speed of dense phase is lower.

2. Wind pressure: The wind pressure in the ducts and pipes of the dilute phase conveying system is lower than that of the dilute phase conveying or dense phase pneumatic conveying. The pressure of the dilute phase is lower, and the pressure of the dense phase is higher.

3. Abrasion: Abrasion refers to the crushing of powder. In dilute phase transport, the loss can be very large due to the speed of particle movement. When it comes to dense phase conveying, the situation is just the opposite, because in these processes, bulk materials are usually conveyed at a lower speed to keep the materials intact and not easily broken.

4. Pipe size: The pipe size of the dilute phase transportation system is often larger than the pipe size of the dense phase transportation system. The various components used in these pneumatic conveying systems are also slightly different in terms of specifications, because their optimal performance depends on the particles they carry and their abrasiveness or sensitivity.

5. Cost: The cost of building a dense phase conveying system is usually higher, mainly because of the specifications of the components. Compared with the dilute phase conveying system, the dense phase conveying system is relatively stronger.

6. Load capacity or ratio: The dilute phase pneumatic conveying system has a low solid-gas mass load ratio. In contrast, the dense phase system has a very high solid-gas mass load ratio.

7. Distance: The maximum conveying distance of dense phase conveying and dilute phase conveying is also different: the conveying distance of dilute phase system is longer, while the conveying distance of dense phase system is generally shorter.

Post time: Nov-29-2021