What is pneumatic conveying ?

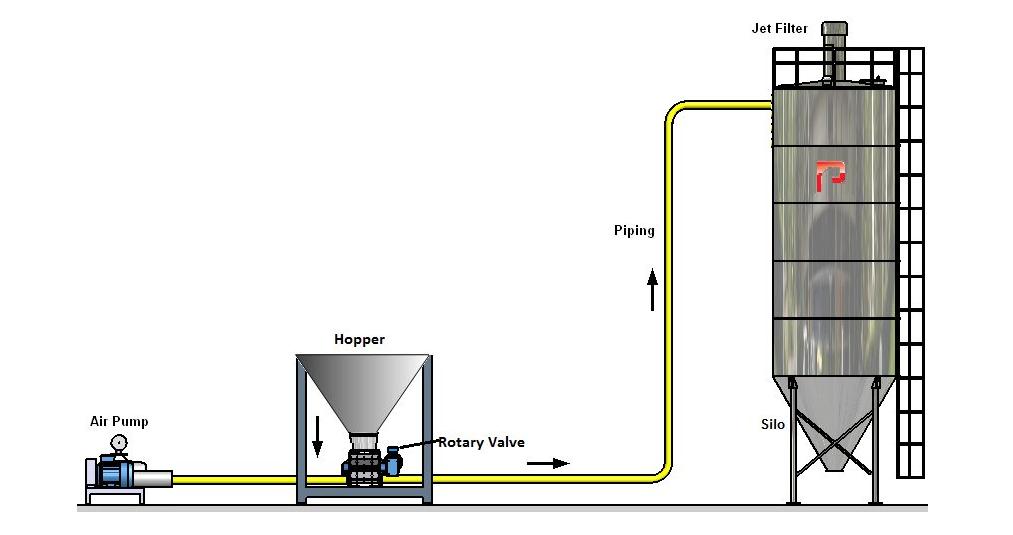

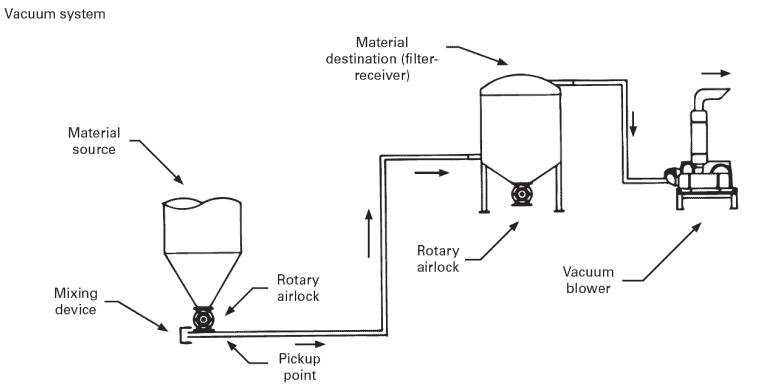

Pneumatic conveying is the transport of bulk solids through a pipe by using the flow of air or other gas. ... Pneumatic transportation can be built as a positive pressure or vacuum system.

Pneumatic powder conveying uses the energy of air flow. Pneumatic conveying is also called air conveying or air conveying system. A specific application of fluidization technology to transport granular materials along the direction of the airflow in a closed pipeline. The layout of the pneumatic conveying device is simple and easy to operate. It can be used for horizontal, vertical or oblique transportation. During the transportation process, physical operations such as heating, cooling, dry-friendly flow classification, or some chemical operations can also be performed at the same time.

According to the density of particles in pipeline transportation, pneumatic transportation is divided into:

1. Dilute phase transportation: the solid content is less than 100kg/m3 or the solid-to-gas ratio (the mass flow rate ratio between the solid transportation volume and the corresponding gas consumption) is 0.1-25. The operating gas speed is relatively high (about 1830ms, according to the gas pressure in the pipeline, it is divided into suction type and pressure delivery type. The pressure in the pipeline is lower than atmospheric pressure, self-suction feeding, but it must be unloaded under negative pressure, and it can be transported roughly. The distance is shorter; the pressure in the latter pipeline is higher than the atmospheric pressure, and the discharge is convenient, and it can be transported for a longer distance, but the powder particles must be sent into the pressure pipeline by a feeder.

2. Dense phase transportation: the transportation process where the solid content is higher than 100kg/m3 or the solid-gas ratio is higher than 25. The operating air speed is low, and a higher air pressure is used to form an air delivery system. Intermittent air-filled tank type dense phase transportation. Put the particles into the pressure tank in batches, and then ventilate them to loosen them. When the pressure in the tank reaches a certain pressure, open the discharge valve and blow the particles into the conveying pipe for transportation. Pulse conveying is to pass a compressed atmosphere into the lower tank to loosen the material; another pulse compressed atmosphere flow with a frequency of 2040min-1 is blown into the inlet of the feed pipe, forming alternately arranged small columns and small sections in the pipe The air column uses atmospheric pressure to push forward. Dense phase transportation has large transportation capabilities, can be pressed for a long distance, material damage and configuration wear are small, and energy consumption is also less. When carrying out dilute phase transportation in a horizontal pipeline transportation system, the gas velocity should be relatively high so that the particles are evacuated and suspended in the airflow. When choosing dilute phase conveying or dense phase conveying, it is designed according to conveying output and powder material performance.

Post time: Nov-22-2021